OEM/ODM Factory Laser Welding - 400W 600W Automatic YAG laser welder for mould refurbishing – Dowin Detail:

Features

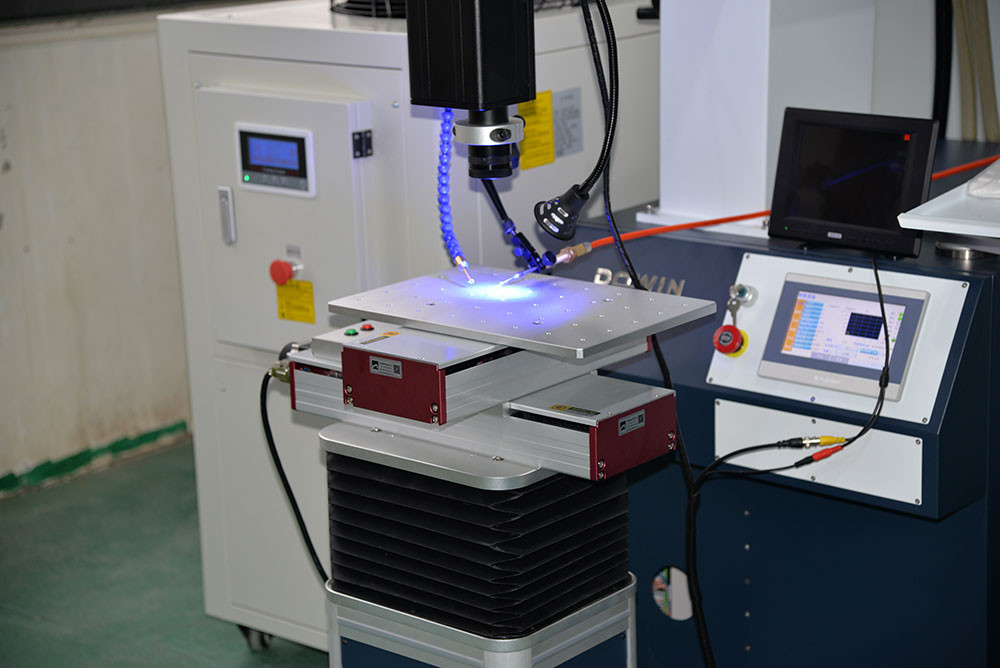

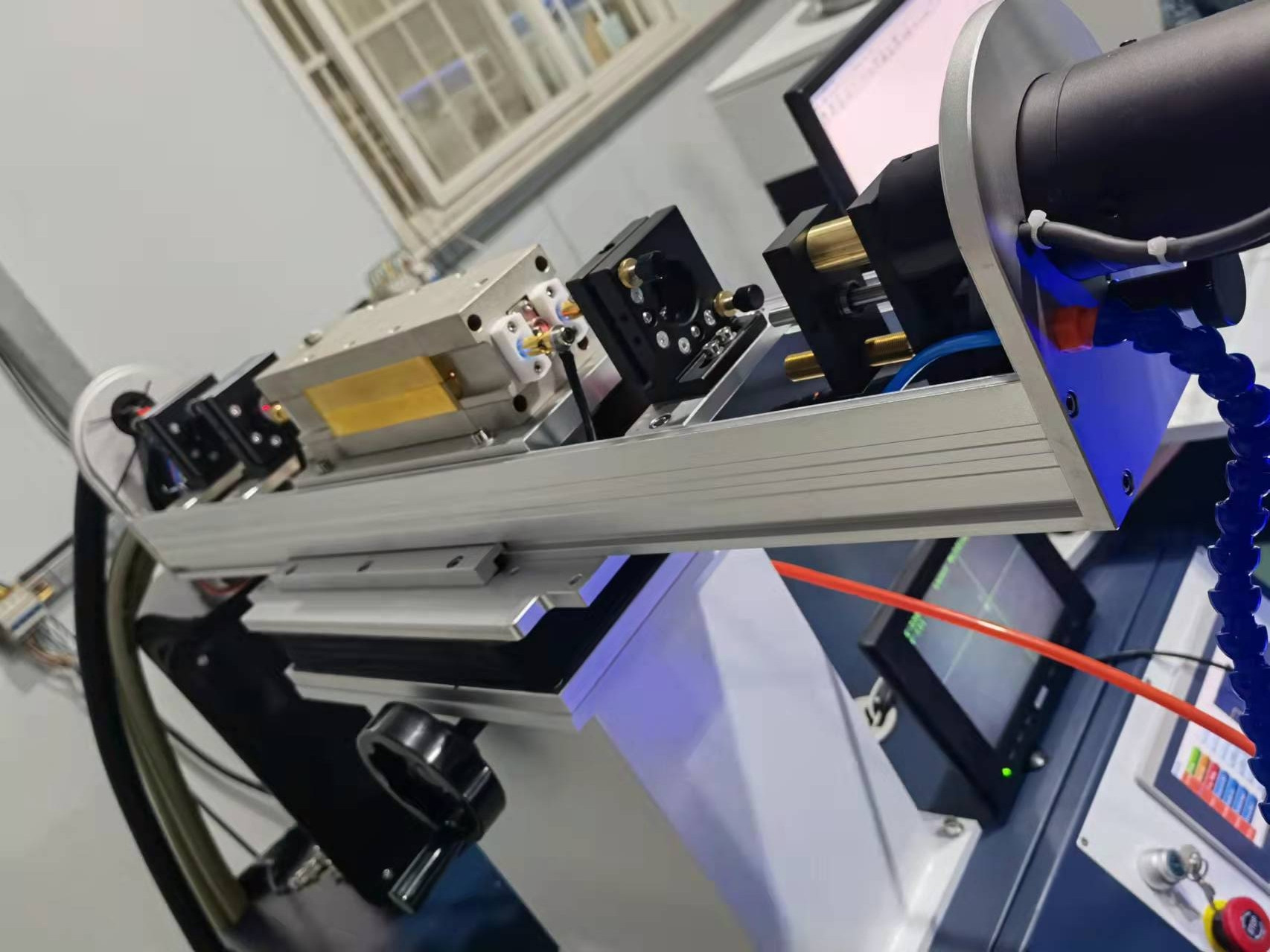

● This Automatic laser welder use electric XY Working table, auto focus laser head ,could welding on curving surface controlled by software.when use Rotary, it is 4 axis automatically ,Could add Automatic wire feeding system.

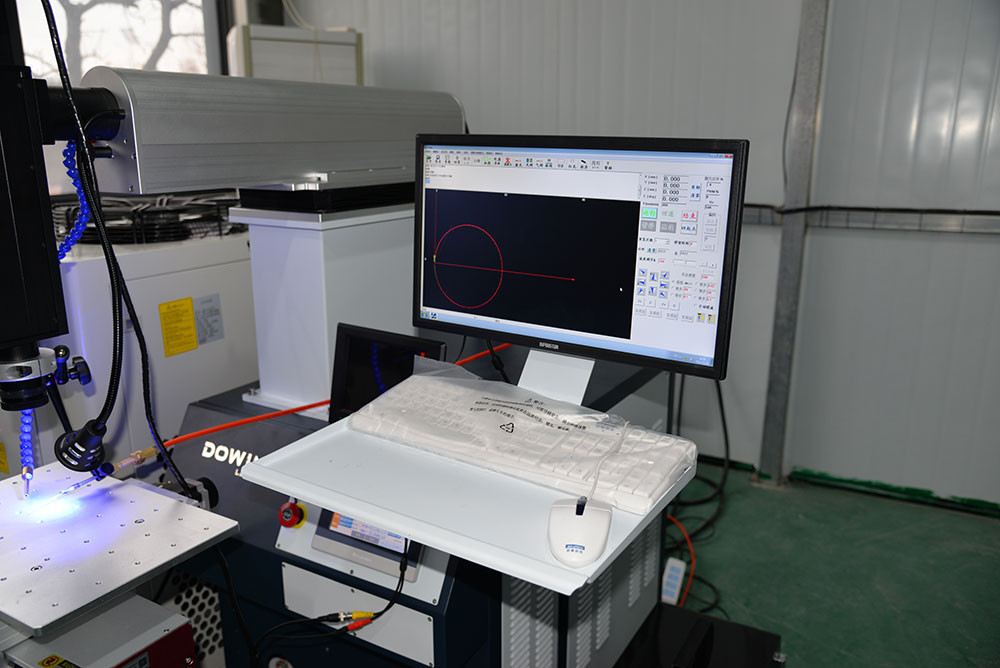

● CNC2000 Software and computer and CCD viewing system free with machine.

● Output power, frequencies, the pulse width and other parameters of the Laser set up directly in system.

● PLC controls Workbench moving speed & directions (forward, backward, left or right), produce a flat and tidy welding line or welding point to optimize the results.

Video introduction

Please check Video to see more details and how it works introduction:

Tech Specifications

|

Models |

DW- 400A DW-600A |

|

|

Travel Path(X, Y, Z) |

X=300mm ,Y=200mm,Auto X & Y Axis and focus control by software .Electrical adjust Z Axis. |

|

|

Worktable Bearing Load |

100KG |

|

|

Machine Weight |

380kg 450kg |

|

|

Power Supply |

220V±10%/50Hz/60Hz / 380V±10%/50Hz/60Hz |

|

|

Laser Type |

Nd:YAG Pulse |

|

|

Laser Spot |

0.1-3mm |

|

|

Wavelength |

1064nm |

|

|

Pulse Width |

0.5-25ms |

|

|

Max. Average Power |

400W 600w |

|

|

Whole Power |

12KW 17Kw |

|

|

Pulse Frequency |

0-100Hz |

|

|

Focusing Size |

110mm |

|

|

Chiller |

Water Cooling System Bingyue 2.8KW chiller |

|

|

Observing System |

CCD |

|

|

Protective Gas |

Argon |

|

|

Welding Wire Dimension |

0.1-1.0mm |

|

Gold coated metal cavity, ensure long life span and strong power

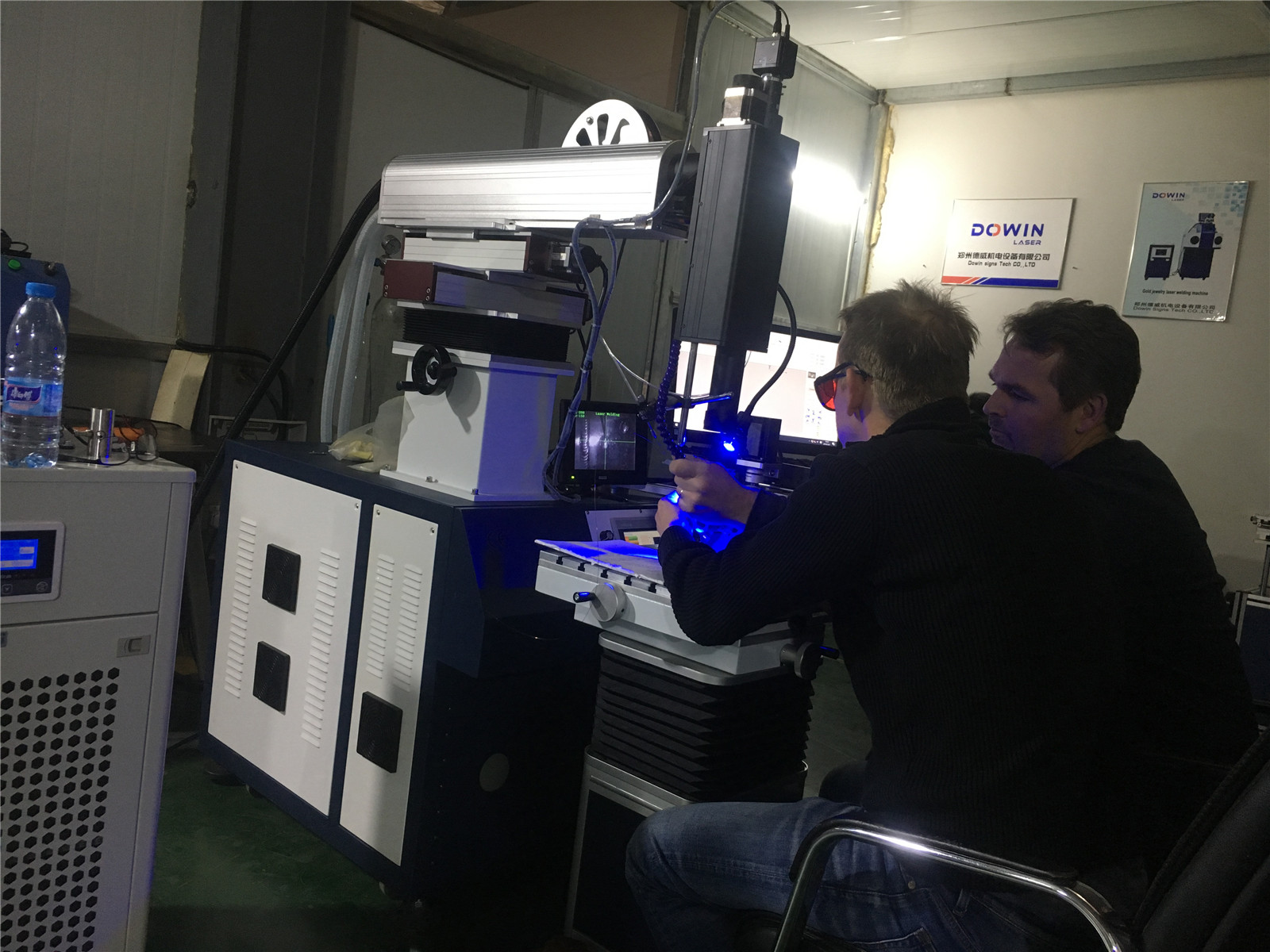

Offer free factory training

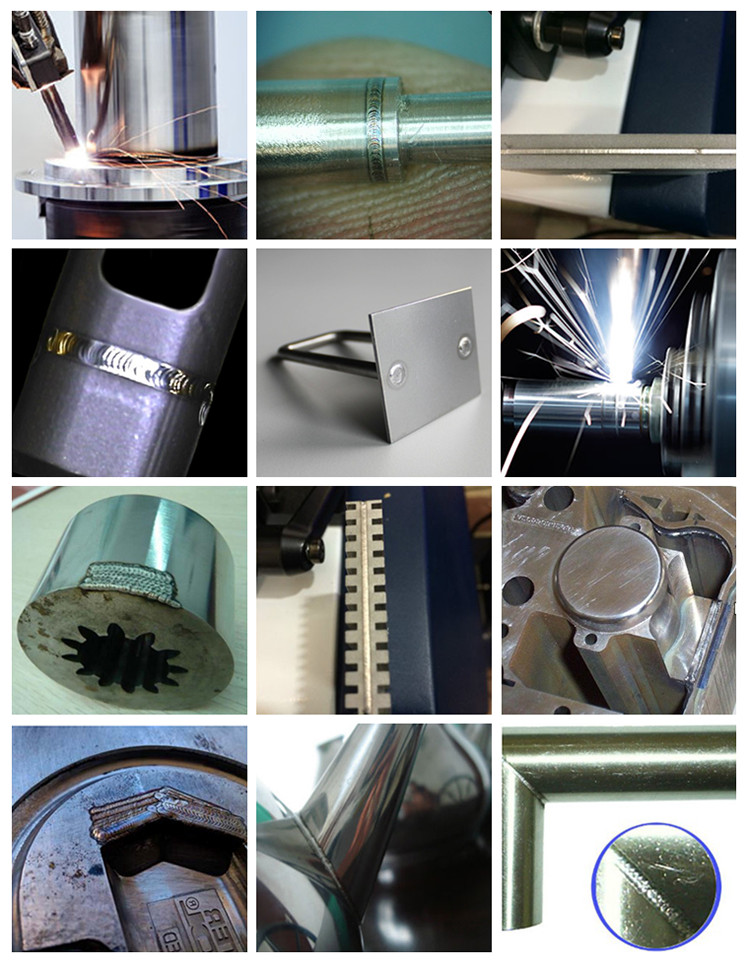

Application materials

1.What material do you need to laser process?

2.Do you need wire feeder

3.Could you send materials to us for free testing?

4.Your company name, website, Email, Tel (WhatsApp…)?Are you reseller or need it for your own business?

5.How do you want to ship it , whether do you have your own forwarder?

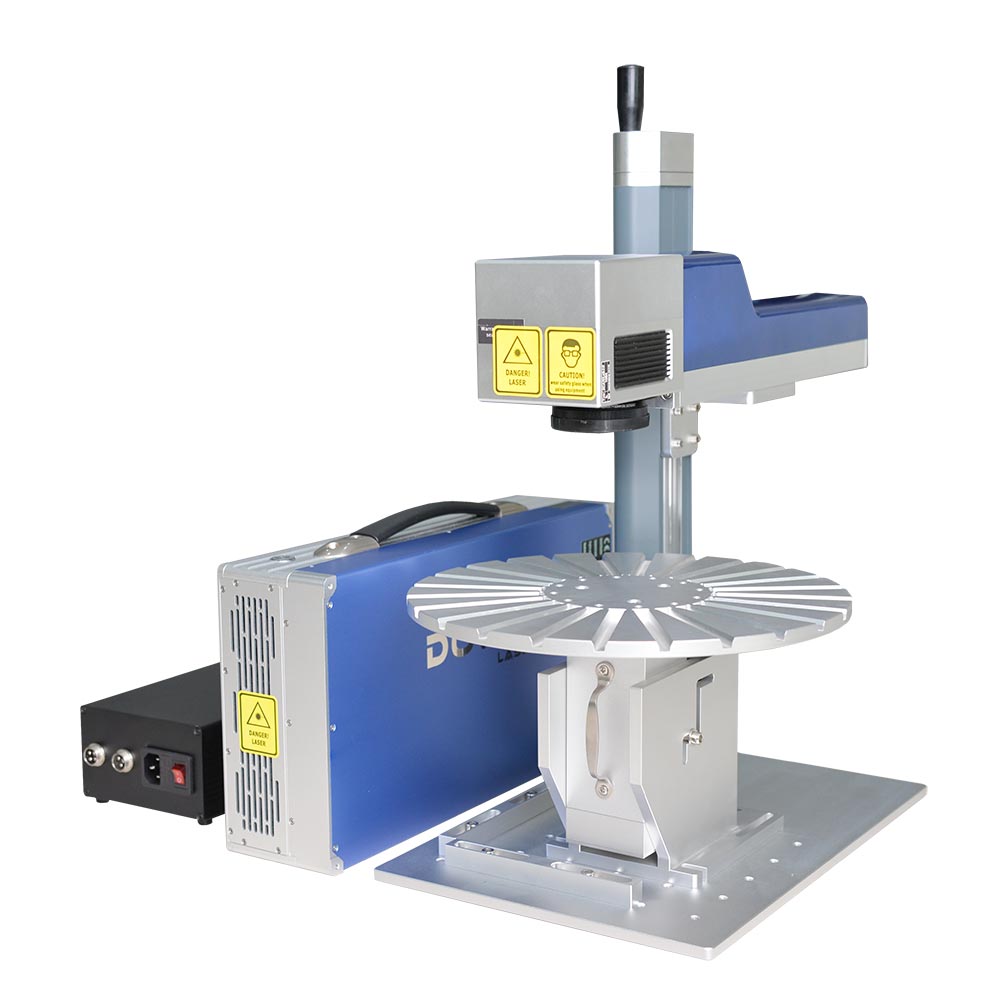

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for OEM/ODM Factory Laser Welding - 400W 600W Automatic YAG laser welder for mould refurbishing – Dowin , The product will supply to all over the world, such as: Lyon, Sudan, Estonia, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.

-

Phone

-

E-mail

-

Whatsapp

-

Top