| Laser welding botebo | ts'epe e sa beng le mabali | tšepe ea carbon | koporo | Aluminium |

| 1000w | 4mm | 4mm | 1mm | 2mm |

| 1500w | 5mm | 5mm | 2mm | 2.5 limilimithara |

| 2000w | 6mm | 6mm | 2mm | 3.0 limilimithara |

02

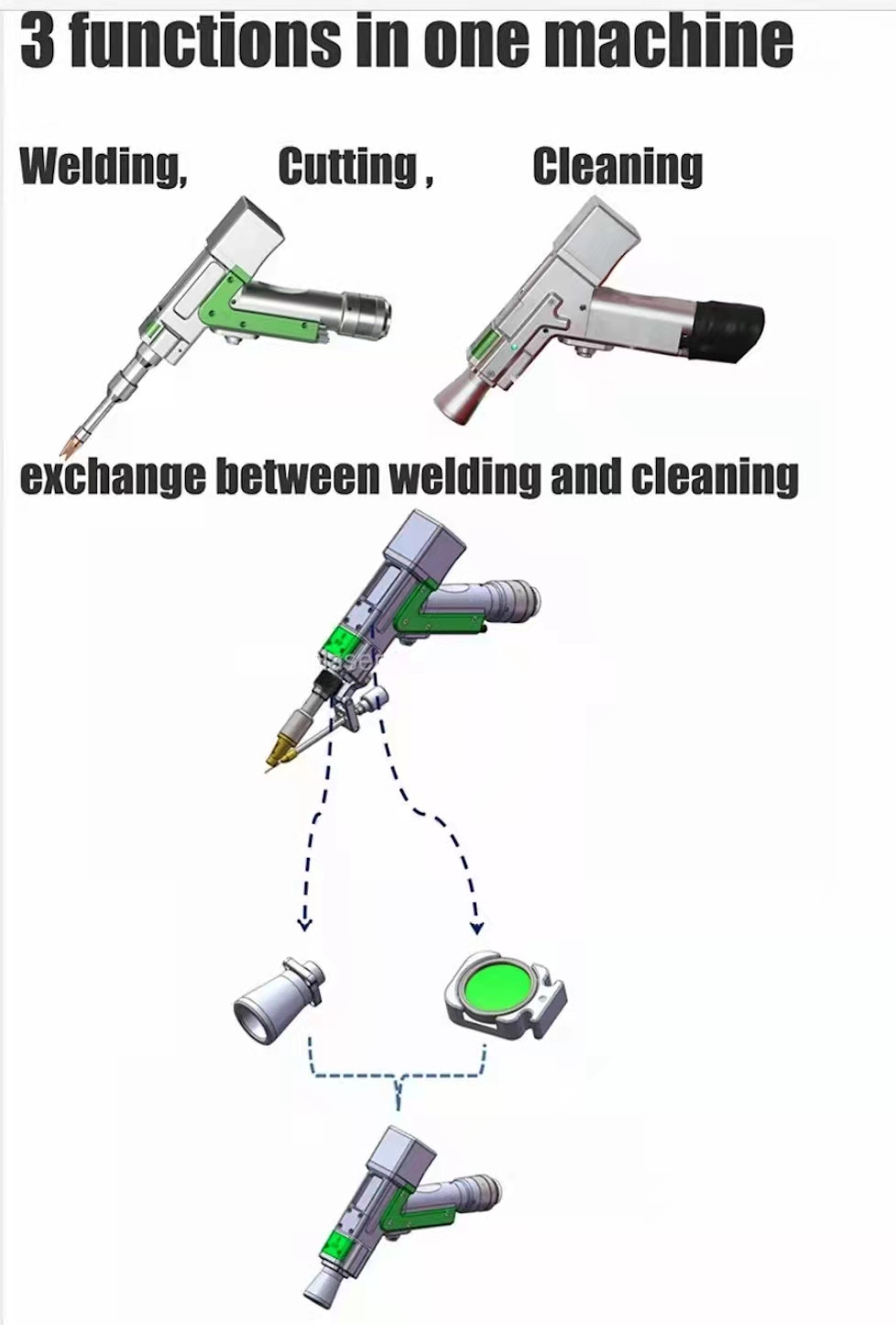

Mosebetsi oa 2: Ho khaola fiber laser ka letsoho

Fiber cutting e sebelisoa bakeng sa liindasteri tse fapa-fapaneng tse kang mokhabiso oa papatso, thepa ea kichineng, mechine ea boenjiniere, tšepe le tšepe, koloi, tšepe ea tšepe ea tšepe, tlhahiso ea li-air-conditioner, ho itšeha ha tšepe, joalo-joalo chelete e hlokahalang ka letsoho ho itšeha.

03

Mosebetsi oa 3: Ho hloekisa Laser

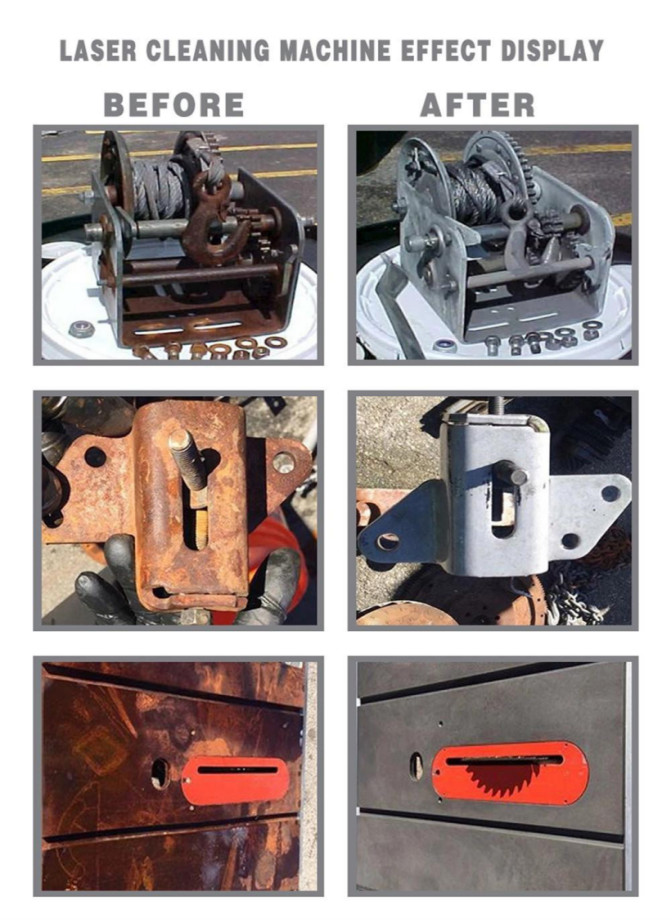

Mechini ea ho hloekisa ka laser e ka boela ea bitsoa mechine ea ho tlosa mafome a laser.Ka bobeli li sebelisa maballo a matla a matla a laser ho khantša bokaholimo ba mosebetsi ka theknoloji ea laser, e le hore litšila, mafome a mafome kapa masela a ka holim'a metsi a fetohe mouoane hang-hang kapa a eboloe, 'me bokaholimo ba ntho e hloekisang bo tlosoe ka lebelo le phahameng. .sehokelo kapa ho roala, ka sepheo sa ho fihlella ts'ebetso e hloekileng.

Lisebelisoa tse ling tsa tšepe tse kang khauta, silevera, koporo, tšepe le aluminium li ka sebetsoa.Ho fapana le mekhoa ea khale ea ho hloekisa mochini, mekhoa ea ho hloekisa lik'hemik'hale le mekhoa ea ho hloekisa ka ultrasonic, ha e hloke leha e le efe CFC organic solvents tse senyang ozone layer.E tla senya sesebediswa mme ha e na kotsi ho mmele wa motho le tikolohong.Ke theknoloji e "tala" ea ho hloekisa.Mochini oa ho hloekisa ka laser o ka sebelisoa bakeng sa ho tlosa khabone ea likotoana tsa lipalo, ho hloekisa mesaletsa ea setso, ho tlosa mafome a clutch, decontamination ea weld, ho tlosa pente ea sefofane, le ho tlosa alloy ea titanium.E sebelisoa e le mokhoa o ratoang oa ho hloekisa liketsahalong tse kang oli.